View STOCK's Premier Batch Sterilization Solution - ImmersaFlow™

RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

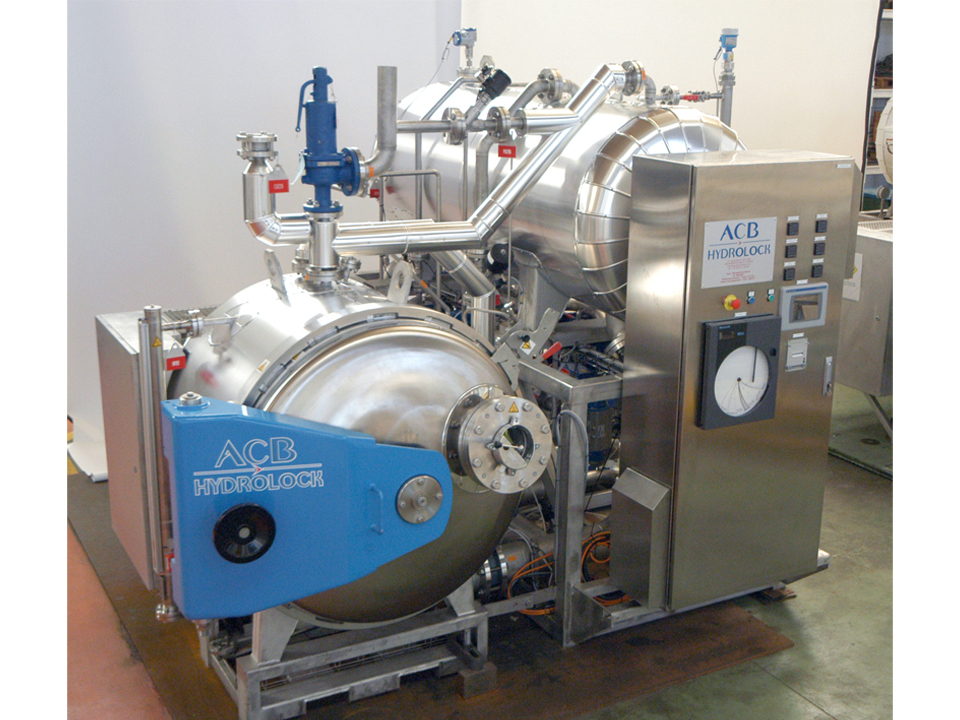

When customers need more than products simply moved from point A to point B, ProMach’s Handling solutions can accumulate, position, feed, orient, flip, stack, load, unload, distribute, rotate, reject, push, divert, index, and perform numerous other intricate product handling challenges. And when customers need to deliver shelf stable products to the marketplace, ProMach’s Sterilizing solutions span the entire range of retort technologies, from entry-level systems to entire automated retort rooms. ProMach backs these solutions with cellular line integration and engineering services to automate entire portions of production lines to achieve optimal performance.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn more- STOCK multifunctional pilot retorts provide the flexibility to develop and optimize heat transfer and sensory profiles for multiple container geometries and recipe formulations utilizing various process and agitation modes

- Develop seamless process transitions for production sterilization equipment employing our ICON sterilization management system

- Available on-board linear deflection container sensor automatically generates the perfect auto-overpressure setpoint ramp and hold steps. Completely eliminate the guesswork of pressure profile development

- New multi-process and agitation modes

- Standard stainless steel construction

- Award winning ICON SMS controls